In the world of surface mount technology (SMT), reflow soldering is far from a simple “heat-cool” process-it is a precise physical and chemical feast taking place on a microscopic scale. Engineers often liken the reflow oven to a modern-day “alchemical furnace,” and the temperature curve that runs through it is the formula that controls this alchemy. How to accurately tune this curve to achieve the perfect balance between production efficiency and soldering quality is the core challenge for every SMT process engineer.

Engineering Fundamentals of the Temperature Curve: Four Key Stages

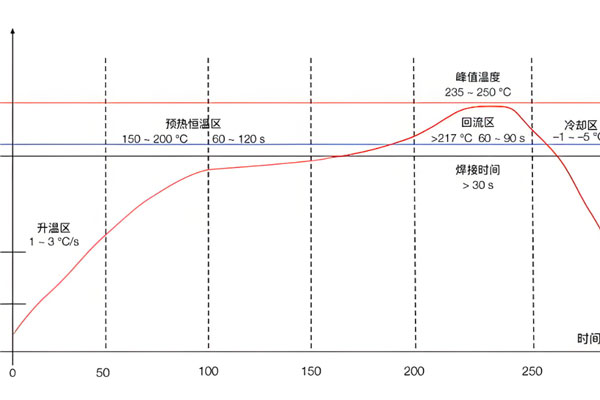

A standard reflow soldering temperature profile is divided into four key stages based on its thermodynamic characteristics and the physical and chemical changes of the solder paste. Precise control of the parameters in each stage is essential for obtaining high-quality solder joints.

1.Preheat Zone

Objective: Achieve uniform heating of the PCB and components, activate the flux, and prevent deformation of components or the PCB due to thermal shock.

Key Parameters: Ramp rate, temperature uniformity. A typical recommended ramp rate is 1–3°C per second. Too fast a ramp can generate significant thermal stress, leading to cracking of brittle components such as multilayer ceramic capacitors (MLCCs); too slow reduces production efficiency and may cause premature volatilization of the flux.

Technical Points: The length and temperature settings of the preheat zone must ensure that the temperature difference (ΔT) between the hottest and coldest points on the PCB is controlled within 5°C. This is key to achieving uniform heating.

2. Soak Zone

Objective: Bring the entire PCB to the activation temperature range of the solder paste (typically 150–180°C), ensuring the flux fully wets the pads and leads, effectively removes oxides, and brings all components close to the melting point.

Key Parameters: Soak temperature, time. This stage generally lasts 60–120 seconds. Too short a time results in insufficient flux activation and poor wetting; too long may cause excessive volatilization of solvents in the paste, affecting wetting during the subsequent melting phase.

Technical Points: By the end of the soak zone, the temperature across all points on the PCB should be nearly uniform, laying a solid foundation for entering the reflow zone.

3. Reflow Zone

Objective: Supply the necessary heat for the solder paste to melt and wet the pads and leads, allowing the solder alloy to fully melt and form an intermetallic compound (IMC) layer, establishing a reliable metallurgical bond.

Key Parameters: Peak temperature, time above liquidus (TAL). The peak temperature is typically set 20–40°C above the melting point of the solder alloy (e.g., for Sn63Pb37 paste, the peak is around 215–230°C). TAL refers to the time the solder remains above its liquidus temperature and is one of the most critical parameters for forming reliable joints, generally recommended to be between 45–90 seconds.

Technical Points: Too short a TAL can result in insufficient solder flow, leading to cold solder or open joints; too long a TAL may cause the IMC layer to become too thick, making the joint brittle and reducing reliability, or even damaging heat-sensitive components.

4. Cooling Zone

Objective: Control the solidification process of the solder joints to form smooth, dense joints with good mechanical properties.

Key Parameters: Cooling rate. A recommended cooling rate is 3–4°C per second. Rapid cooling can refine solder grain structure and improve joint strength. However, too rapid cooling (>10°C/second) can generate excessive thermal stress and may cause component misalignment or tombstoning.

Technical Points: Avoid opening the furnace door at the beginning of the cooling zone. Sudden introduction of cold air can cause uneven PCB temperatures and thermal shock, compromising solder joint quality.

Tuning Methodology: A Closed-Loop Optimization from Data to Practice

Tuning the temperature profile is a scientific process based on data analysis and continuous improvement—not guesswork.

Data Collection

Use a temperature profiler with multiple thermocouples, precisely attaching them to critical locations on the PCB—such as under the most densely packed components, at the edge of the board, under large heat sinks, and at the center of BGAs. This is the only way to obtain accurate data.

Data Analysis

Compare the measured profile with the process window:

Evaluate Uniformity: Check the ΔT at the end of the preheat zone.

Evaluate TAL: Ensure it falls within the target window.

Evaluate Peak Temperature: Confirm it is within the safe range and does not overheat any components.

Identify Defects: Infer root causes from the curve shape. For example, a steep preheat slope may correspond to tombstoning or component cracking; insufficient TAL may lead to cold solder or open joints; excessive peak temperature may result in a thick IMC layer or component discoloration.

Parameter Adjustment

Based on analysis, make systematic adjustments to the oven:

Adjust Conveyor Speed: Directly controls the duration of each stage and is the most direct way to adjust TAL and overall cycle time.

Adjust Setpoints of Each Zone: Fine-tune the shape of the temperature curve. For example, to improve uniformity, raise the temperature of the front zones or lower the rear ones.

Adjust Airflow: In forced convection ovens, airflow directly affects heat transfer efficiency and uniformity. Adjusting airflow can resolve local temperature deviations.

Balancing Efficiency and Quality in Engineering

“Faster and better” is the eternal pursuit of manufacturing engineering. In reflow soldering, “fast” means higher line speed and shorter cycle times; “good” represents lower defect rates and higher product reliability. Optimizing the temperature profile is fundamentally about finding the best balance between these two goals.

A skilled process engineer must not only understand the theory behind the temperature curve but also be able to translate that theory into practice. Through precise data collection, rigorous analysis, and scientific adjustments—continuously iterating and optimizing the process window—one can truly master the “alchemy” within the reflow oven, achieving efficient, stable, and high-quality mass production and securing a competitive edge in the marketplace.