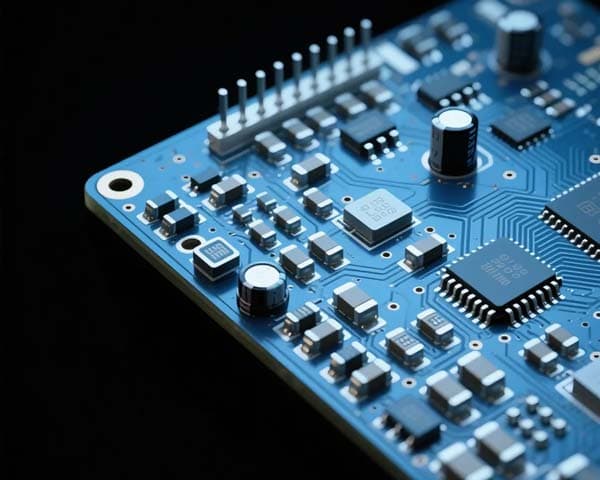

In the intricate world of Surface Mount Technology (SMT) assembly, where thousands of components are soldered onto a single printed circuit board (PCB) in minutes, quality is often measured in micrometers and milliseconds. Yet, despite this precision, a single “bad point”—a microscopic defect like a cold solder joint, a misaligned component, or a tiny solder bridge—can be the difference between a functional device and catastrophic failure. This is the SMT quality “vital line”: an invisible threshold where one minor flaw triggers a chain reaction of consequences, from production delays to life-threatening hazards.

- The Domino Effect on Manufacturing Efficiency

At first glance, a single defect seems trivial. However, in high-volume SMT production, it can halt an entire assembly line. Consider a cold solder joint on a critical power management IC. During automated optical inspection (AOI), this defect might be flagged, requiring the board to be pulled from the line for manual rework. This single intervention disrupts the flow, causing downtime, increasing labor costs, and reducing throughput. In worst-case scenarios, if the defect is missed by AOI, it progresses to testing, where functional failures may require scrapping the entire board, wasting materials and time. - Compromised Product Reliability and Performance

Beyond production, a single bad point can cripple a product’s performance. A tombstoned resistor (a component that stands on end during reflow) can create an open circuit, causing a device to malfunction intermittently. A solder bridge between two fine-pitch pins on a processor can lead to short circuits, resulting in data corruption or system crashes. These defects may not manifest immediately, making them even more dangerous. - Safety Hazards and Life-Threatening Risks

In critical applications like medical devices, automotive safety systems, and aerospace electronics, the consequences of a single bad point are far more severe. A faulty solder joint in a pacemaker could cause the device to fail, endangering a patient’s life. A defective sensor in an autonomous vehicle’s braking system might fail to detect obstacles, leading to accidents. In aerospace, a single bad point in a satellite’s communication system could result in the loss of a multi-million-dollar mission.

These scenarios underscore the non-negotiable nature of SMT quality in safety-critical systems. The “vital line” here is not just about performance—it’s about human lives. Even the smallest defect, if overlooked, can have irreversible consequences. - The Root Cause: Why One Bad Point Matters

A single bad point rarely occurs in isolation. It is often a symptom of deeper issues in the SMT process: poor solder paste printing, incorrect reflow temperature profiles, or inadequate component handling. For example, a misprinted solder paste deposit can lead to insufficient solder, causing a weak joint. A faulty component placement machine might repeatedly misalign components, creating defects across multiple boards.

This is why SMT quality control focuses on prevention rather than detection. Techniques like Statistical Process Control (SPC), Automated X-ray Inspection (AXI), and Design for Manufacturability (DFM) are used to identify and eliminate root causes before defects occur. The “vital line” is not just about catching bad points—it’s about ensuring they never happen.

In SMT assembly, quality is a chain where every link—solder paste printing, component placement, reflow soldering, inspection—must hold. A single bad point is more than a defect; it is a threat to efficiency, reliability, and safety. As electronics become smaller and more complex, the margin for error shrinks, making the SMT quality “vital line” more critical than ever. For manufacturers, crossing this line is not an option. In the world of SMT, perfection is not just a goal—it’s a necessity.