In the SMT (Surface Mount Technology) assembly process, solder beads and solder bridging are two of the most common and frustrating issues. Not only do they affect the aesthetic appearance of the circuit board, but they can also lead to electrical short circuits, functional failures, and even compromise product reliability. Many factories find themselves repeatedly reworking and debugging during mass production, often overlooking the importance of prevention from the source. This article, drawing from practical production experience, shares several practical tips to help you effectively avoid solder bead and bridging problems, thereby improving production yield and efficiency.

I. Causes and Dangers of Solder Beads

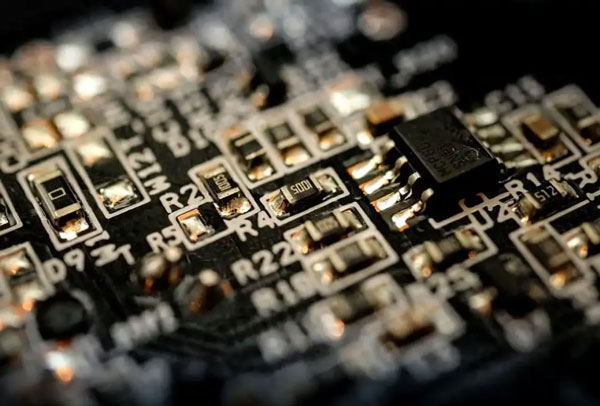

Solder beads are small, spherical particles of solder that form around the pads during the soldering process, typically with a diameter between 0.1mm and 0.3mm. Their formation is often related to factors such as solder paste printing, reflow soldering temperature profile settings, and component layout.

Although a single solder bead may seem insignificant, on high-density circuit boards, it can bridge adjacent pads, causing an electrical short circuit. Especially in precision electronic products, solder beads can lead to signal interference, device restarts, or even component burnout. They are a defect type that must be strictly controlled during the production process.

II. Manifestations and Risks of Solder Bridging

Solder bridging, also known as “solder shorting,” occurs when solder accidentally connects adjacent pads or pins, forming an unintended conductive path. It is commonly seen during the soldering of fine-pitch components like ICs, QFPs, and BGAs.

Solder bridging not only disrupts the designed logical function of the circuit but can also cause intermittent failures due to cracking from thermal expansion, contraction, or vibration during subsequent use. This increases after-sales repair costs. Therefore, preventing solder bridging is a key step in enhancing product reliability.

III. Practical Tips to Avoid Solder Beads and Bridging

1. Optimize the Solder Paste Printing Process

Solder paste printing is the first step in the SMT process and a major factor influencing solder beads and bridging. The following measures are recommended:

Select the appropriate type and particle size of solder paste: For fine-pitch components, use a fine-particle solder paste (e.g., Type 4) to ensure printing precision.

Control printing thickness: Excessively thick solder paste can lead to solder beads, while too thin a layer may cause dry joints. It is generally recommended to use a stencil thickness between 0.10mm and 0.15mm, and adjust the aperture ratio appropriately according to the pad size.

Clean the stencil regularly: Solder paste residue can affect the quality of subsequent prints. It is recommended to clean the stencil after every 5-10 PCBs.

2. Properly Set the Reflow Soldering Temperature Profile

The reflow temperature profile directly affects the melting and solidification process of the solder and is a core control point for avoiding solder beads and bridging:

Control the ramp-up rate during the preheating stage: It should be controlled between 1.5°C/s and 3°C/s to avoid violent volatilization of solvents in the solder paste, which can cause splattering.

Ensure uniform and stable temperature in the reflow zone: This ensures the solder is completely melted but avoids excessively high temperatures that could increase fluidity and cause bridging.

Maintain a moderate cooling rate: A controlled cooling rate helps form good solder joints, but too fast a rate can lead to thermal stress concentration. A rate of 3-4°C/s is recommended.

3. Scientifically Design PCB Pads and Component Layout

Optimization during the PCB design phase can fundamentally reduce soldering defects:

Match pad sizes to component leads: Pads that are too large can easily cause solder beads, while pads that are too small may lead to dry joints. It is recommended to design according to IPC standards.

Avoid excessively small pad spacing: For fine-pitch components, the pad spacing should be ≥0.2mm, and the width of the solder mask should be appropriately increased to prevent bridging.

Arrange component orientation and density reasonably: Avoid concentrating high-density components in one area. Leave sufficient space for solder flow and reduce thermal interference.

4. Use Appropriate Soldering Auxiliary Materials

Flux selection: A low-solid-content, high-activity flux helps improve wettability and reduces the risk of solder beads and bridging.

Match solder paste to components: Different component packages have different requirements for solder paste. For example, it is recommended to use silver-containing solder paste for BGAs to enhance joint strength.

5. Strengthen Process Monitoring and Equipment Maintenance

Link SPI (Solder Paste Inspection) and AOI (Automated Optical Inspection): Set up inspection points after printing and after soldering to detect abnormalities in a timely manner.

Regularly calibrate the reflow oven temperature: Ensure the temperature zones are stable to avoid quality issues caused by temperature drift.

Train operators: Strengthen process discipline awareness to prevent process fluctuations caused by human error.

While solder beads and bridging are common, they are by no means uncontrollable. By optimizing solder paste printing, scientifically setting the reflow profile, rationally designing PCB pads, selecting appropriate auxiliary materials, and strengthening process monitoring, the occurrence of these two defects can be significantly reduced. In actual production, process engineers should uphold the philosophy of “prevention first, continuous improvement,” perfecting every detail to achieve efficient, stable, and low-cost SMT assembly. We hope the tips shared in this article will be helpful to you, ensuring that every circuit board you produce can withstand the test of the market.