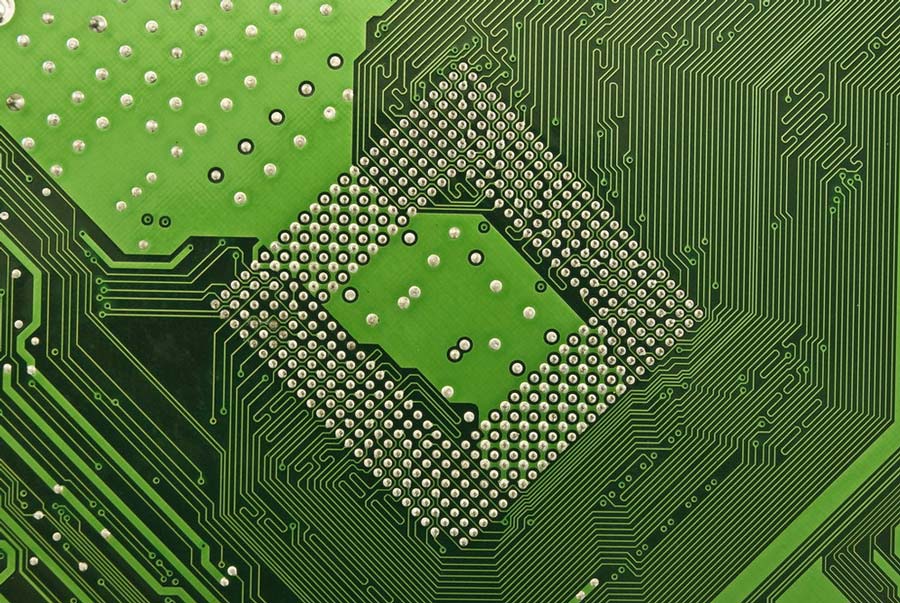

If your project requirements have led you into considering a double-sided PCB design, it is important to understand the assembly process, the pros and cons, and other items you may want to look out for while putting together your design.

Pros: Why Go Double-Sided PCB

Most PCBs that are designed and built are single sided. This means all of the components are on one side and assembly is only required on that one side. The biggest benefit of designing a double-sided board would be to minimize the footprint. If your project has a strict space requirement, it may be beneficial to move some of the components onto that second size to reduce the space it takes in its end product. The second advantage is that due to the additional layer of copper, there’s increased heat dissipation. During the etching process of fabrication, copper is removed to create tracks but instead of leaving it out completely it is then reinserted.

Cons: Why to Keep PCB Single-Sided

Having a double sided PCBA is essentially like having 2 separate PCBs with additional hurdles. This means double the stencils, double the stencil printing, double the programing, double the pick and place, double the reflow, and so on. This leads to he costs of assembly increasing. If your project has a strict budget or lower margins, it might be beneficial to figure out how to make a single sided PCB work. Double-sided PCBs also have additional things to look out for during manufacturing. Since they are run through the reflow oven twice, it is important to look at heavier components possibly falling off on the first side during the second reflow. Heat sensitive components and heavier components on the “second” side of the board may improve manufacturability. If the double -sided board is mixed technology and has through hole components in addition to SMT parts, wave soldering may not be possible and hand soldering will need to be done which means additional costs.

Double-sided PCB Conclusion

In conclusion, both single and double-sided PCBs are important in the electronics space. They each have different uses and it is important to understand their nuances to get your design started. Since the boards are built in different manners, its useful to understand how to improve manufacturability to mitigate discrepancies and keep costs manageable. Lastly, cost is different due to double-sided boards having to have twice the assembly. Based on the final application, budget, and other factors, you can decide on whether single-sided or a double-sided PCBA works for you.

If you’re not sure which board you need, then get in touch with us via [email protected] and we’ll be happy to discuss your project requirements and advise on the best methods for your needs. Having us as a partner will help ensure you get quality PCBAs designed, manufactured, and into the hands of your customer.