The PCB industry has witnessed several changes over the years and one such was the transition from rigid to flexible circuit boards. For several years, engineers used to create flex circuit boards by connecting multiple small rigid boards with cables. This is because flex circuit board fabrication was a tedious process and quite expensive, too. However, today, they have become much common and are found in everything from wearable technology devices to smart devices, and many more. What makes these flex PCBs popular over rigid boards? Will rigid boards become a rarity in the PCB industry? Read this post to know the answers.

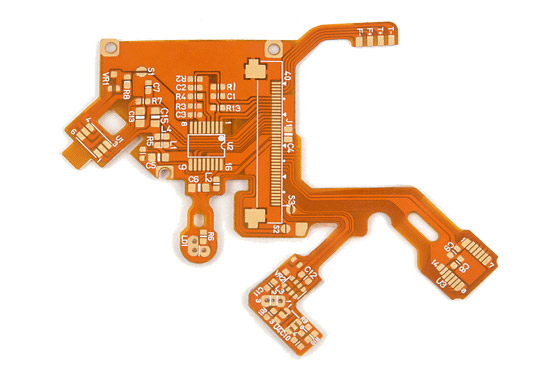

Flex Circuit Boards: Why They Are a Hot Trend in the PCB Industry

Although the prices of flex circuit boards have reduced over the years, they may slightly cost you more than rigid boards. In spite of this, these boards are finding applications in several electronic appliances. The following factors have contributed to their growth:

-Flex PCBs are created from materials that can easily flex and resist vibrations and bending.

-These PCBs are small-sized, and weigh lesser than their rigid counterparts, which helps reduce the product package weight by almost 75%.

-Flexible circuit boards have fewer connection points, thereby allowing limit or avoiding solder joint interconnection defects. This increases their reliability in all types of devices.

-When it comes to flexibility, these circuit boards are not only flexible in their form but also offer flexibility in terms of designs. Flex circuit boards can be easily fit into unusual shapes, which makes them popular over rigid designs.

-These boards can be combined with rigid boards to create rigid-flex boards, which combine the best of both rigid and flex designs.

-Flex PCBs allow for better thermal performance and space allotments, which makes them a popular choice for the automotive sector.

-These boards can accommodate a large number of circuit connections, which makes them a popular choice for compact-sized electronics.

-Having said that, does it mean rigid PCBs are no more in demand? Are they slowly fading away from the industry? Read the next section to know more.

A Brief Analysis on Rigid Circuit Boards and Their Utility

Rigid circuit boards have been for more than 50 years and were the first type of circuit boards. These circuit boards are inflexible, thus the name. They can be manufactured in single-sided, double-sided and multilayer configurations. The following are some factors that keep them going in spite of the increasing demand for flex circuit boards.

-A rigid circuit board is much cheaper compared to flexible PCBs. This makes them a choice for applications large applications where the price of manufacturing tends to be on the higher side.

-Although the manufacturing processes for rigid boards have evolved over the years, they still follow much simpler techniques than flex boards, which makes them cheaper.

-These boards are thicker and stronger than flexible PCBs, which makes them a choice in high-power computing applications such as motherboards of laptops and computers, military and defense equipment, medical equipment, and so on.

Although flex and rigid-flex circuit boards are gaining traction, rigid boards are still required in many industries. Owing to their price factors and ease of manufacturing, these boards may never wipe from the industry.