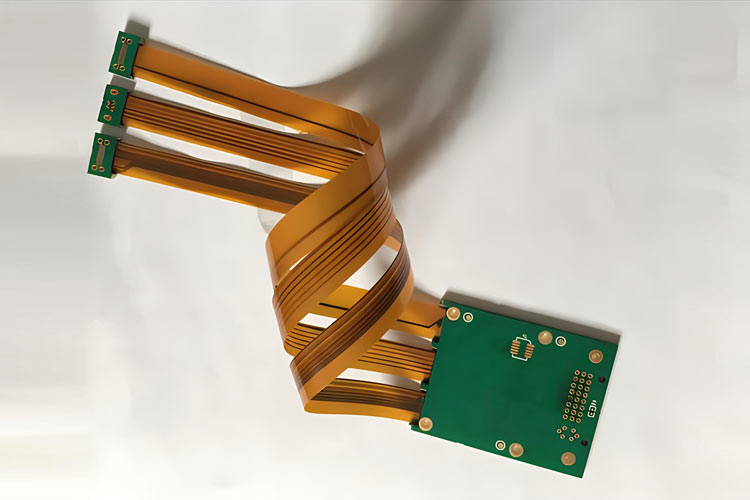

Rigid-flex PCBs are a specialized type of printed circuit board that combines rigid and flexible materials into a single panel. This unique construction allows for fixed and adjustable areas within the identical PCB, offering advantages over traditional rigid or flexible PCB designs.

A rigid-flex PCB typically consists of alternating layers of rigid and flexible substrates laminated using advanced manufacturing techniques. The frozen sections provide structural support and house components, while the flexible cells enable bending and folding without damaging the PCB.

The flexible portions of a rigid-flex PCB are typically made of polyimide or similar materials, known for their excellent flexibility, thermal stability, and electrical insulation properties. These flexible layers can be single-sided or double-sided, accommodating the placement of traces and components on both sides.

Rigid-flex PCBs are highly customizable, allowing for complex three-dimensional designs. They can be manufactured in various shapes, including L-shaped, Z-shaped, or even curved configurations, providing designers with unprecedented flexibility and space optimization opportunities.

Advantages of Rigid-flex PCBs over Traditional PCBs

Rigid-flex PCBs offer several advantages over traditional rigid or flexible PCBs, making them a preferred choice for many advanced electronic applications. Some key benefits include:

1. Space Savings: Rigid-flex PCBs enable the integration of multiple PCBs into a single structure, reducing the overall size and weight of the electronic device. Eliminating the need for connectors and cables between separate PCBs saves valuable space, allowing for more compact and streamlined designs.

2. Reliability and Durability: Combining rigid and flexible materials in rigid-flex PCBs enhances their durability and reliability. The risk of failures due to loose connections, solder joint fatigue, or mechanical stress is minimized by eliminating the need for connectors and reducing the number of interconnects. This results in more robust and long-lasting electronic devices.

3. Improved Signal Integrity: Rigid-flex PCBs offer better signal integrity than traditional PCBs. The potential for signal loss, reflections, and electromagnetic interference (EMI) is significantly reduced with fewer interconnects and impedance mismatches. This ensures reliable and consistent signal transmission, especially in high-speed and high-frequency applications.

4. Design Flexibility: Rigid-flex PCBs provide greater design flexibility, allowing for the creation of innovative and intricate layouts. The ability to bend and fold the PCB enables the placement of components in unconventional positions, optimizing available space. This flexibility also simplifies the design of complex circuits by reducing the need for additional connectors and cabling.

5. Cost and Assembly Efficiency: While rigid-flex PCBs may have a higher initial manufacturing cost than traditional PCBs, they often result in overall cost savings. Integrating multiple PCBs into a single structure eliminates the need for additional connectors, cables, and assembly processes. This reduces assembly time, labour costs, and overall manufacturing efficiency.

Rigid-flex PCBs offer distinct advantages over traditional rigid or flexible PCBs. Their unique construction combining rigid and flexible materials allows space savings, improved reliability, enhanced signal integrity, greater design flexibility, and cost efficiency. Choosing a reliable rigid-flex PCB supplier for wholesale rigid-flex PCBs ensures access to high-quality and customizable solutions for advanced electronic applications.