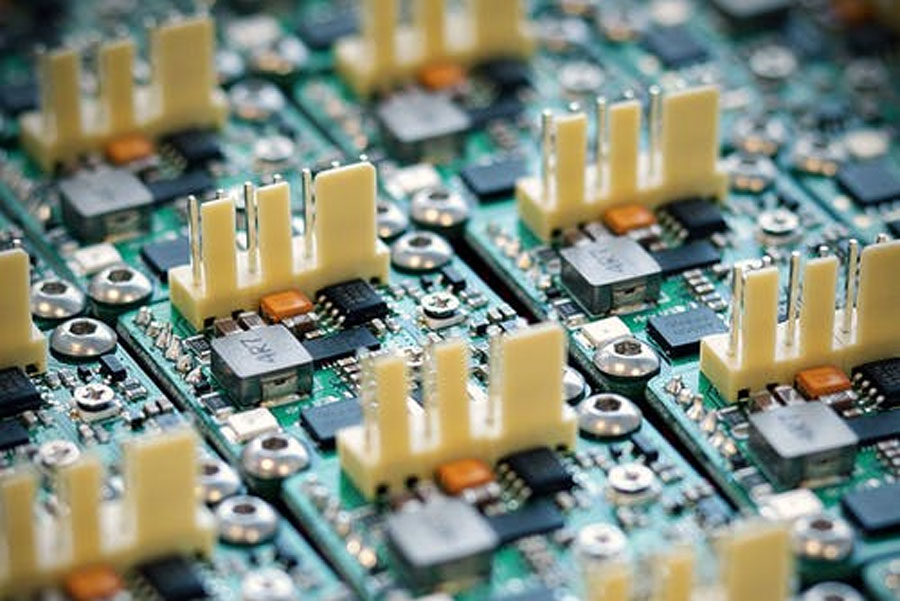

Printed circuit board assemblies are very crucial requirement nowadays. More and more PCBs are being produced and are extensively in use. PCB assembly manufacturing contains numerous complex processes, and it’s going to be quite challenging to build it efficiently.

Efficiency is necessary when it comes to PCB assembly manufacturing. Productive management of PCB assembly manufacturing can increase the overall production rate and even improve its speed.

You have to focus on almost all the factors regarding PCB manufacturing and assembly. Even the smallest points can lead to effective assembly and manufacturing of PCB.

The functioning of a device depends on a PCB indirectly depending on its assembly process. If there are inefficiencies in the PCB manufacturing and assembly, then problems may arise in the device. However, there is a way through which such problems can be solved.

There are various ways and steps to enhance PCB manufacturing assembly efficiency, resulting in a perfect functioning output. Let’s discuss such points below:

Target fewer component variations

In a PCB, you would see different components lying on the same board. Now, they play a very important role in the efficiency of the PCB assembly and manufacturing process. For, they used together to make a whole PCB.

Now, variations in such components can lead to difficulties in the manufacturing process of a PCB. It is to be noted that if different parts of a PCB are taken from different manufacturers, they will be different. Not all manufacturers can produce the same components.

Their components may vary—The size, the shape, and the functions.

If component variations are there, it would be hard for efficient PCB assembly to take place. The component variation should be as lowest as probable in the manufacturing process.

Focus more on PCB assembly-It’s manufacturing & requirement

How do you plan to enhance PCBA manufacturing efficiency if you are unaware of a PCB’s requirements? It is essential to know the conditions of a PCB thoroughly and work accordingly to it.

Here comes the important role of the manufacturing process. You should focus on taking on the manufacturing process in such a way that it can fulfill all the requirements of a PCB. The PCB assembly manufacturing process should ensure that the output would be efficient and of high quality.

You should be aware of every step in the manufacturing & assembly process of a PCB

Each step in the process of PCB assembly adds manufacturing is important. Various problems may arise in such steps and stages. Certain difficulties arise in the different processes leading to quality issues. Through this, the production process can take more time, leading to the late delivery of products. It can be risky since your reliability will lessen.

All those problems will not arise if you are aware of each step taken during the assembly process. It will help you to point out where the mistakes have been made and how you can solve such difficulties. This can help in incrementing productivity rate, and your reliability will be on-point.

You should have enough and necessary materials for production

Materials-They consist of the most important part of the entire assembly process. For, without materials, a PCB would be incomplete. Various problems may be noticed due to minimum stocks of materials during the PCBA manufacturing process.

Unmanageable volumes of raw materials lead to various problems. During the surface mount technology processes, Its materials are often compromised against the PCB management requirements. It results in the degradation of the output quality of the PCB.

Thus, the focus should be made on the matters regarding the materials. One should make sure that the materials are being used efficiently and the stock is enough to complete the entire production process. It can help in enhancing the efficiency of the PCB manufacturing and assembly as a whole.

Monitor the defects of the PCB manufacturing process

Defects during the production processes can be very unhealthy for a PCB. A successful PCB manufacturing and assembly is that when there are no defects as a result. If there are defects, there can be a decrease in the quality of such outputs.

If one does not monitor the defects during the production process of a PCB, then it would only be noticed on the test. If that happens, the production time will increase, and your reliability would lessen.

Nowadays, there are various tools that one can use to test for defects in a PCB. Such tools can be a lot beneficial, and they can point out the problem quickly so that you will have more time to solve it. It can lessen the time you need to look for defects in the PCB, thus reducing production time.

Focus on the conformance and traceability of a PCB

The quality of a PCB is a necessary aspect. There are different means through which ensuring the quality of a PCB is doable. Certain requirements can be noticed for the PCB manufacturing and assembly to be better. Two of such requirements are conformance and traceability.

Traceability is that requirement where if the effect is seen in a PCB, then the manufacturers should be able to point out other defects of the product’s different units. This can help in ensuring that the defect would be solved without having to check all the products.

Conformance helps in keeping a proper procedure of PCB assembly manufacturing. If the PCB manufacturing and assembly process is already and proper, there would be fewer chances of a defect to arise in the output PCB.

Conclusion

People may get confused about whether it is possible or not to enhance their PCB assembly manufacturing efficiency. It should be noted that if they take various measures properly, they can make their PCB efficient. There are various ways to take place, including-Targeting fewer component variations, focusing on a PCB’s requirements, having proper materials, keeping a proper quality of PCB, focusing on the production procedure of PCB, etc.