Managing heat is an important part of printed circuit board design and manufacturing. A board that isn’t designed to dissipate the heat it generates may end up with operational problems or even complete failure. During manufacturing it is also important that the heat be managed in order to withstand the high temperatures applied during the soldering process. Making sure to use adequate PCB heat dissipation techniques for design is very important, and here some recommendations that will be helpful to you on your next project.

Thermal Problems in PCB Operation

Your printed circuit board design is going to generate heat when it is operating, and how much heat will depend on how much power is being used and at what frequencies that the board will operate at. The more that those factors increase, the higher the operating temperatures of the board will be. These higher temperatures will make it more difficult for the PCB to achieve its target performance levels. The goal then is to design the board so that the heat will flow away from the circuits without creating hotspots on the board.

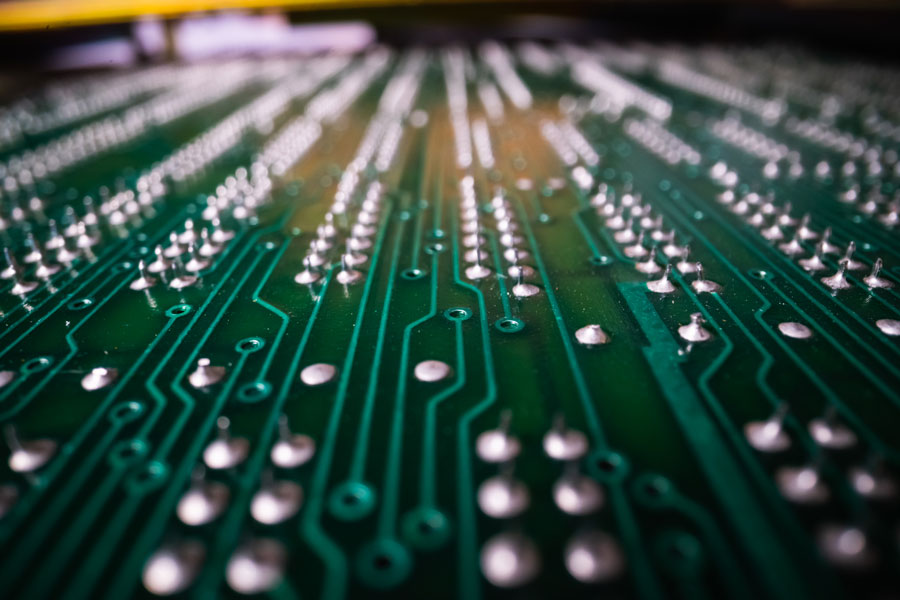

One way to dissipate the heat correctly is to use the board itself as a heat sink. PCB fabrication materials, such as FR-4, are designed to absorb heat and in a lot of cases will satisfactorily handle it. But for higher speed circuitry and boards conducting more power, FR-4 may not be enough. You may have a situation where the copper circuitry will have greater thermal conductivity than the dielectric material of the PCB, and will readily conduct heat through the traces and into other components. In such cases more extreme thermal management techniques need to be incorporated into the design.

Another major area of thermal management is in designing the power supply of the board. These supplies will often need additional efforts to manage their heat that could include heat sinks mounted to them with insulators, thermal compounds, or even being bolted to the board. In some cases you may want to investigate the use of an alternative heat sink such as attaching components to the system enclosure to help dissipate the heat. It is a good practice to evaluate the heat flow with your mechanical design team to find the beat ways to dissipate this heat.

PCB Design Techniques to Dissipate Heat

To handle the greater thermal problems of high speed and high power boards, here are some design techniques that can help:

-Large metal pads under hot parts to act as a “thermal” pas.

-Solid filled vias to conduct heat from thermal pads into ground planes.

-Heat sinks connected to thermal pads of hot parts.

-Using board materials with better thermal properties such as polyimides or metal core boards.

-Cooling fans as well as strategic component placement to put hot components into the circulating path of the fan.

Make sure that your hot parts can set squarely on its thermal pads. Any voids under the pads can heat up and negate the effectiveness of the thermal pad. Also watch for any bumps from solder on the thermal pad as that can prevent a good solid contact to the part to conduct the heat.